[10000ダウンロード済み√] 2.5 d vs 3d cnc 165072

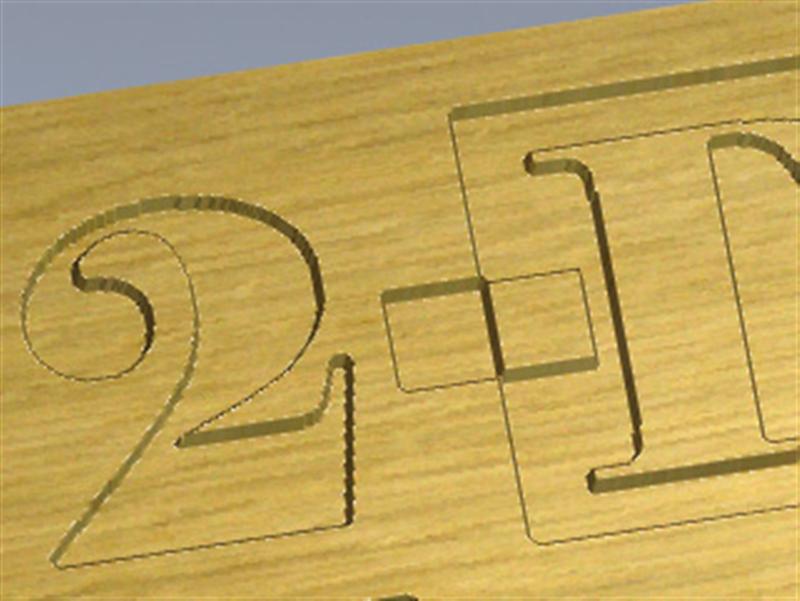

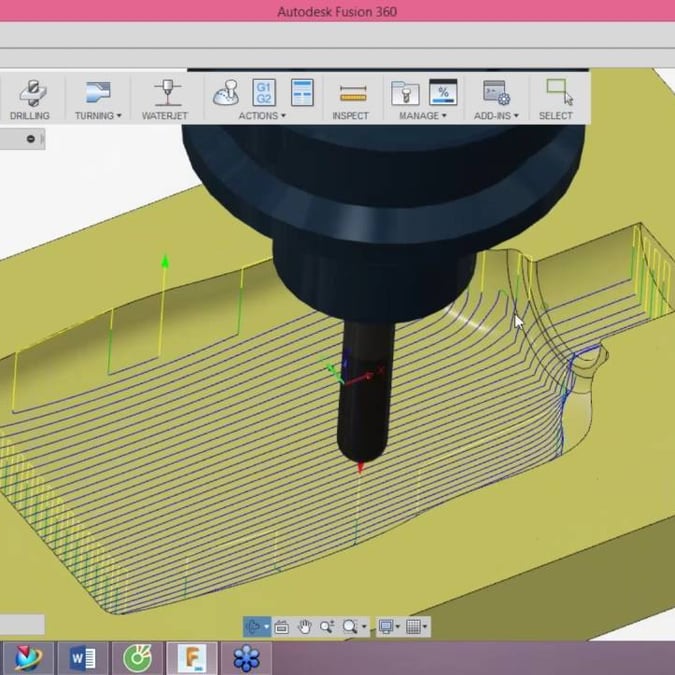

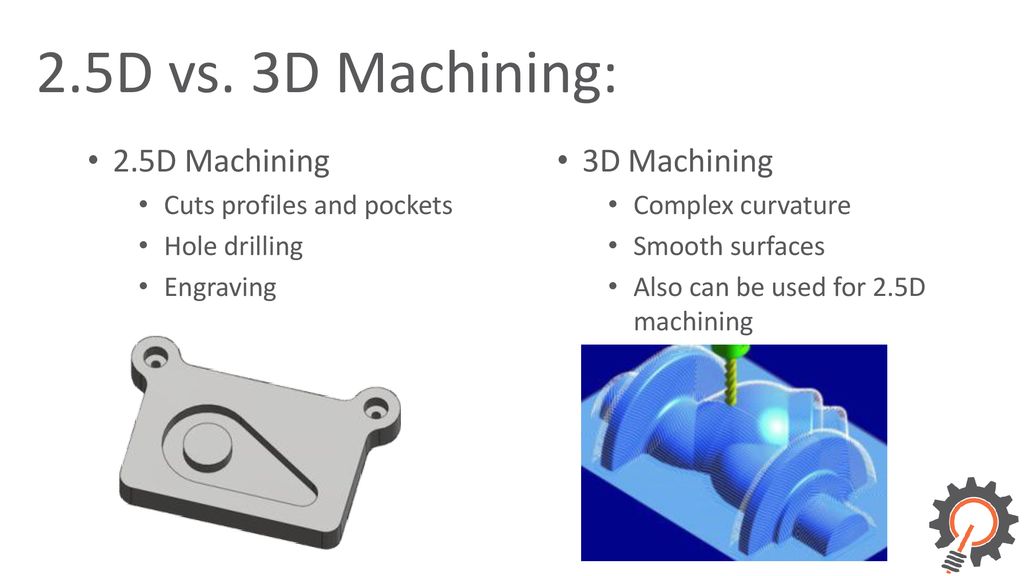

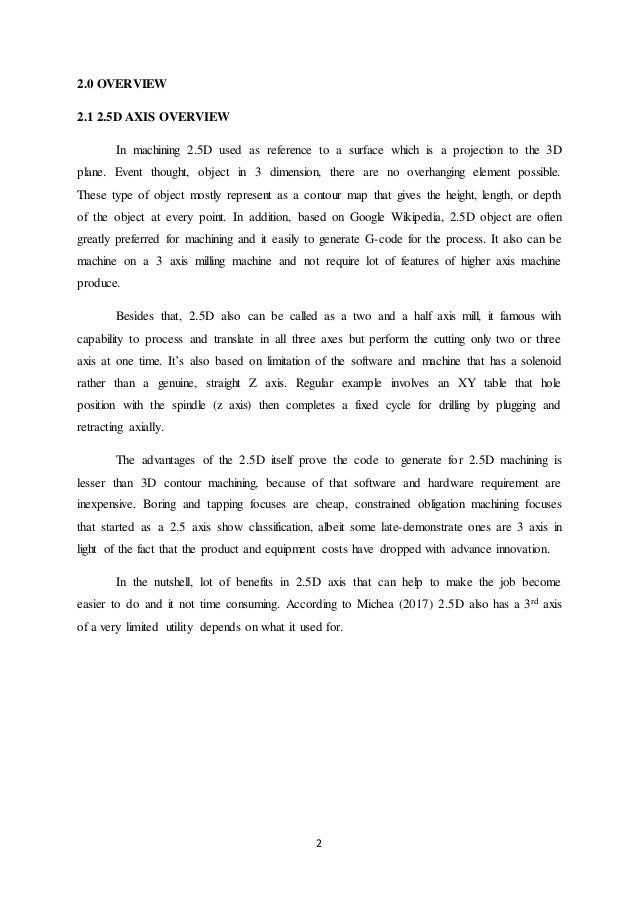

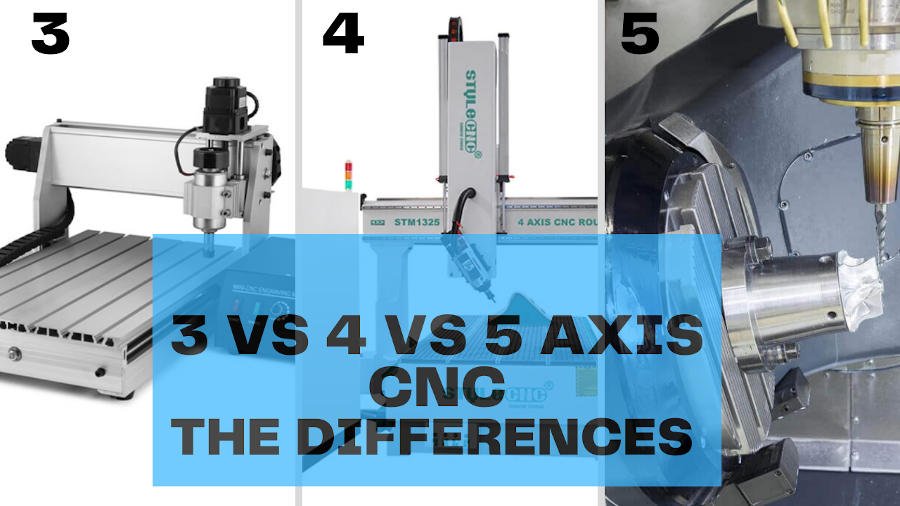

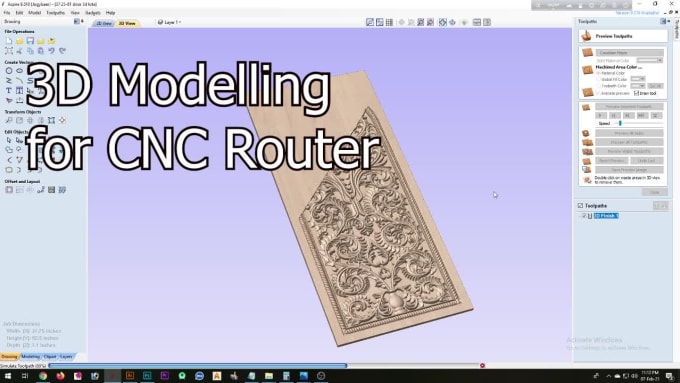

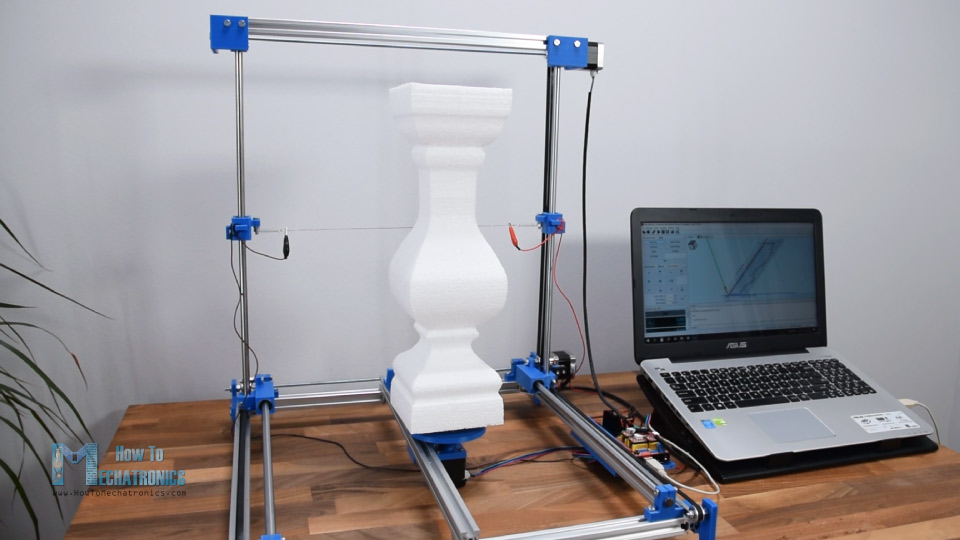

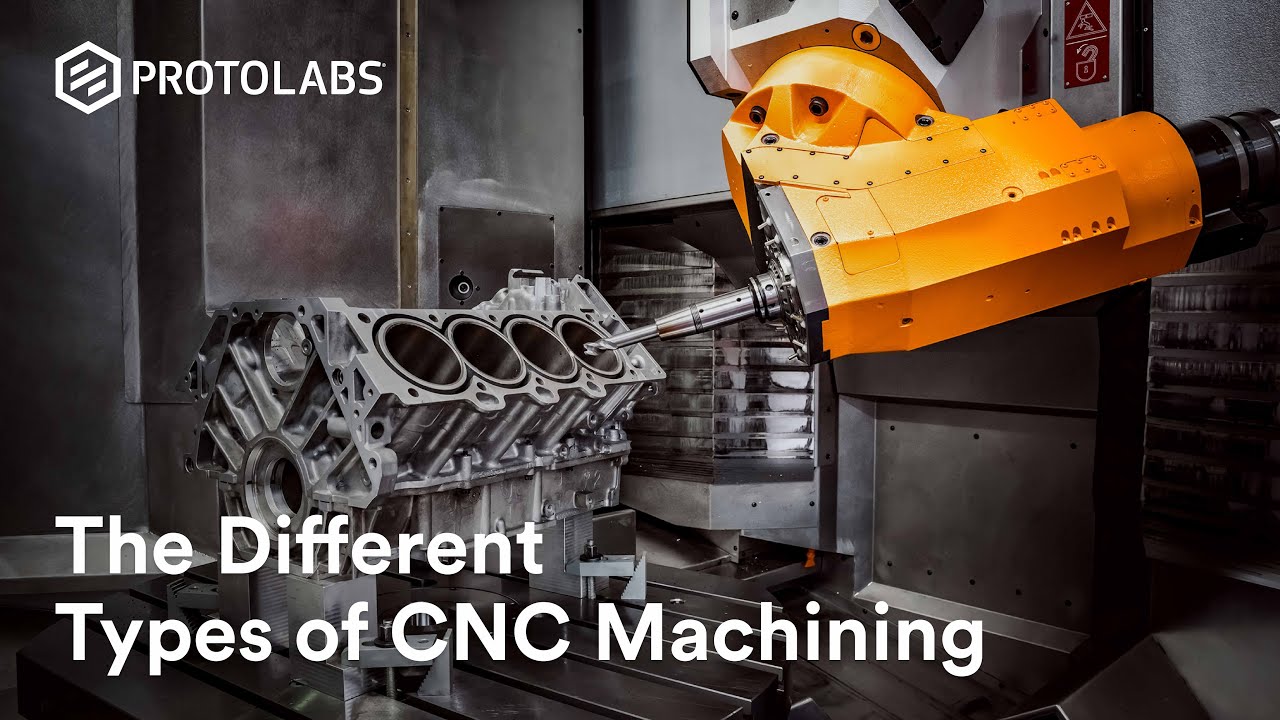

25 Axis or 25D CNC 25D refers to a machining scenario in which there are no overhanging elements to the part In other words, everything that must be reached can be reached by plunging straight down from above 3 Axis or 3D CNC Refers to a machine or CNC scenario that has 3 axes of motion available, usually X, Y, and ZSnapmaker Modular 3in1 3D Printer unlocks your full creative potential, from 3D printing to laser engraving, cutting, and CNC carving Smarter, faster, larger, and more powerful than ever before, it is a new generation of 3in1 3D printer that comes with everything you needSolidCAM puts the most powerful 25D programming solution at your fingertips, right inside your CAD systemSolidCAM looks, feels and performs like your existing CAD systemIn addition to its powerful 25D milling Profiling, Pocketing and Drilling operations, SolidCAM's 25D module includes Simplified geometry selection using CAD sketches, autofeature recognition and

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

2.5 d vs 3d cnc

2.5 d vs 3d cnc- I have been trying to learn more about CNC and have found alot of good info, but one area all the resources I've found seem to think does not need explaining is 2D vs 25D CNC machines 3D is obvious, all 3 axes are controled at the same time You can complete a part start to finish (3D model, generate tool paths and export Gcode) with Autodesk fusion 360, which comes with integrated HSMworks cam, 25 D is $300 /yr commercial and free for hobbyists up to 5 axis machining is available for $10/yr I have actually left my more expensive solutions for this one

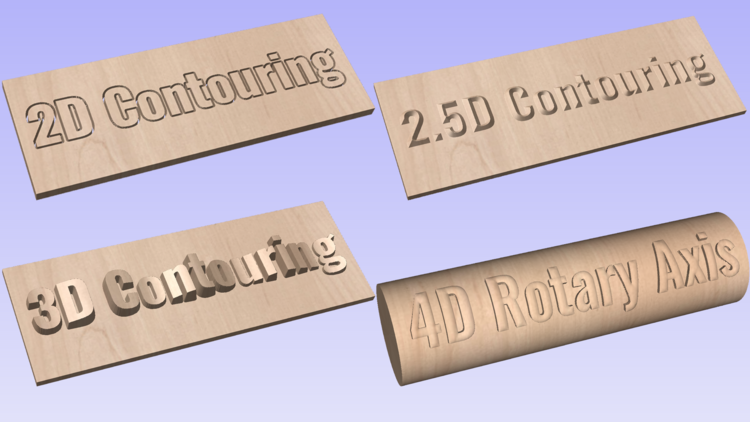

What Is The Difference Between 2d 2 5d And 3d Contouring Learn Your Cnc

There is no such thing as a half dimension, so the term 25D is really a nonsense term, and has no intrinsic meaning That said, 25 is "somewhere between" 2 and 3, so 25D generally means something In this guide, I review the best free CNC software programs available today Further, I have sorted the software programs into categories based on their capabilities For CNC Router Machines, you generally have four types of software 1 CAD software To create a 2D or 3D graphical model of the part you wish to make 2 Rhino would be overkill if you are working with a 25D mill Rhino is powerful for designing complex 3D shapes but its not so hot for 25D designs as it takes a lot of rework when you need to make design modifications and its human interface is fairly "unique" I'd start with one of the free 2D CAD packages

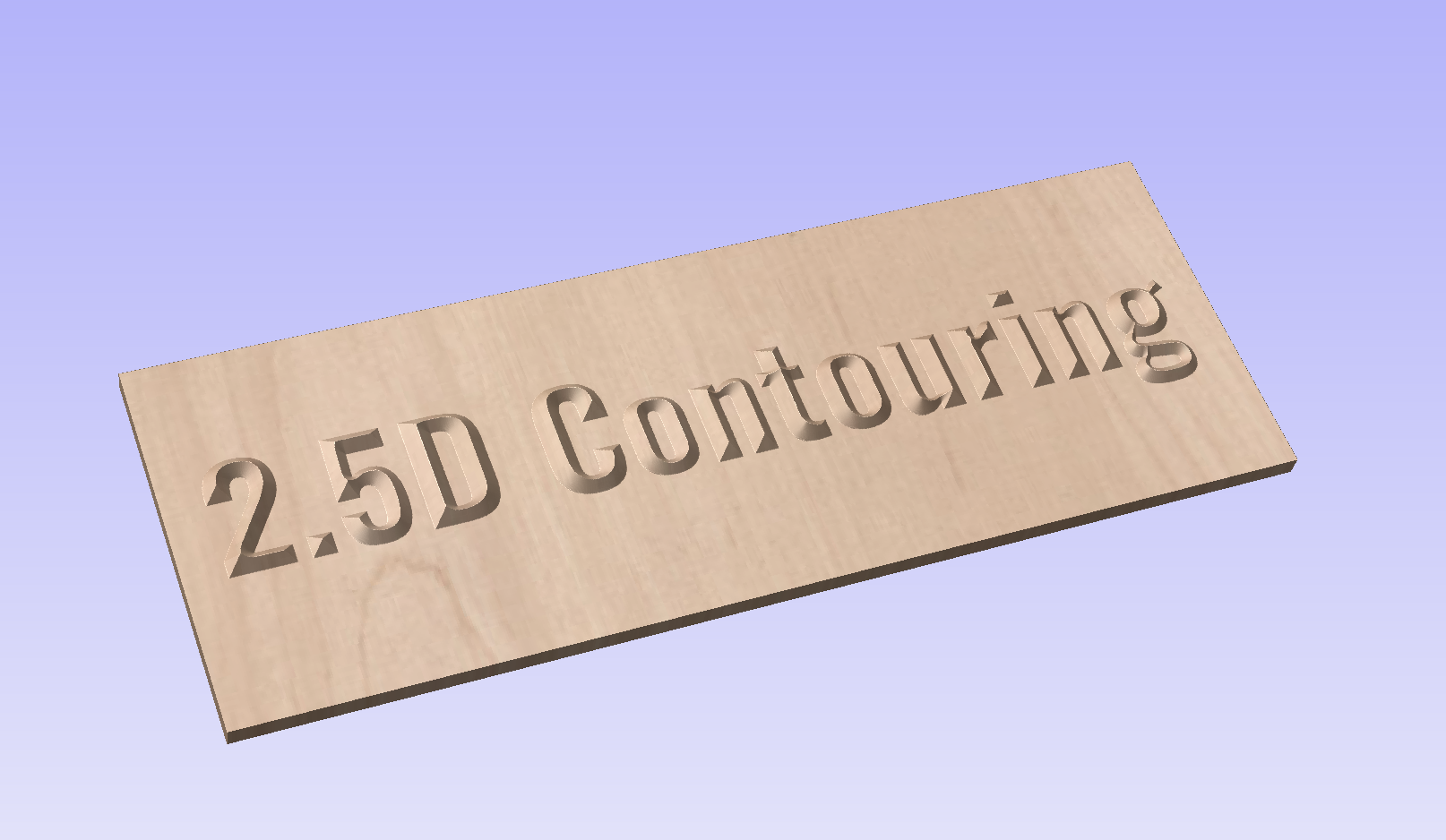

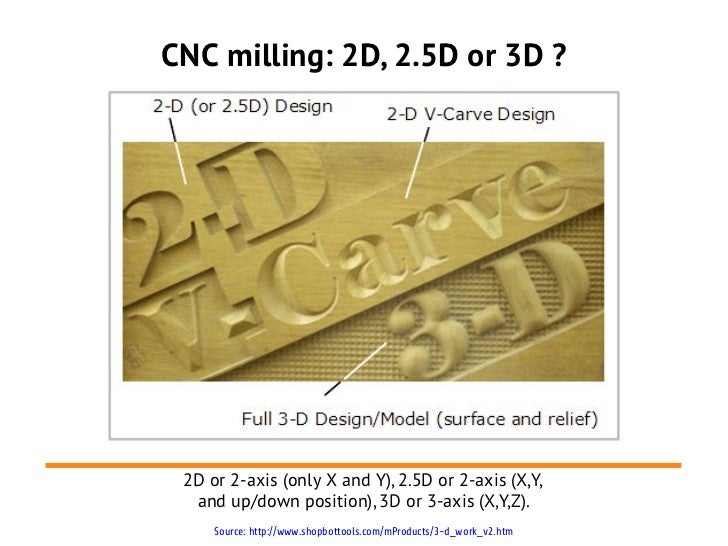

2D vs 25D vs 3D Carving Part 36 Aspire and VCarve For Absolute BeginnersMore down here ↓↓↓ Click SHOW MORE!This is the 36th in a series of videos geareOthers have commented on machine design and capability but it is also a CAM distinction, 25d is cuts at particular depths and 3d is contouring, like bowls and boat hulls and car bodies For example a cabinet shop may have a 3d capable machine but only use it for 25d workNo products in the Quote Working in two dimensions (2D) means that you are cutting out a part with features that are all at the same depth This is common for laser, hotwire, water jet, and plasma cutting, along with engraving The FlashCut CNC software's DXF Import feature

Easist way to check for the difference between 21/2D and 3D is to get clear and type in something like G01 X Y Z F40 If it's a 3D machine it will move all three axis and do a diagonal move in all axis If it's a 21/2D it will either move Z first then X and Y or even just move X and Y and ignore Z We've noticed a trend lately that advanced 3D printing people are calling their normal print setup as 25D, not 3D The idea is that while the machine has 3 axes, the actual geometry generati With 25D milling, there are multiple features on the workpiece This uses the X and Y axes for the toolpath as well as the Z axes, where there is a difference in depth or features on the workpiece With 3D milling, the three axes can cut to different depths, and create different shapes

Probing Cnc Cam Software Open Mind

Affordable 3d Cnc Routers 3d Cnc Machines For Sale Stylecnc

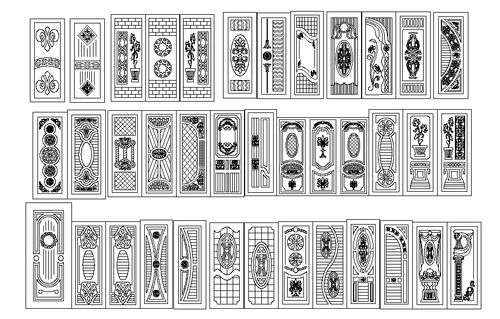

It's not 3D It's not 2D It's 25D!If you want more sources on learning this stuff, then here are some places you can go toWikipedia https//enwikipedia 25D is where the X and Y can be commanded together in synchronisation but the Z can only be raised and lowered on its own 3D is X Y and Z can all be synchronised Mach can synchronise 6 axis HoodIntuitive user interface that makes it simple to draw and edit any 2D and 25D shape FlashCut CAM creates accurate tool paths instantly with fingertip control to cut precise parts FlashCut 2D and 3D CAM generates perfect tool paths for plasma, oxyfuel waterjet, laser, or marking

3d Stl Models 2 5d 3d Stl Dxf Cnc Model Fish Bowl Etsy

What Is The Difference Between 2d 2 5d And 3d Contouring Learn Your Cnc

3D means 3 axis of movement, that can be X,Y and Z Most VMCs are capable of simultaneously moving these 3 axis while the spindle is turning, that is the definition of 3D machining 25D typically means that you move Z to a height and then X and Y move, then Z is adjusted to a new height and X and Y move againAnswer (1 of 6) Always fun to get an A on an older question Thanks In regards to computer modeling, and not CAM/CNC machines 2D "modelling" is using a 3D(or more) capable modeling program as a flat two dimensional CAD/drawing tool This – 25D or 3D milling can be done in a slanted surface – Canned cycles or custom cycles can be used – Same feature on different planes can be machined using the same program • Similar to 3D Coordinate Conversion, but more comprehensive • In the past, it was limited to 3 axis compensation, ie, only G43 and G41/G42 can be used

China 2 5d 3d Milling Machine Tool Changer Cnc Carving Machine Manufacturer For Polishing Drilling Milling Chamfering Cutting Grinding Carving Engraving China 2 5d 3d Tool Changer Milling Machine Cnc Carving Machine Manufacturer For Polishing

Messing About With The Cnc Router

A few months ago, when I was 100% new to all this, I found "25d" to be a pretty confusing concept in particular, and "which machines can do 2d vs 3d" unclear in general I think that your description is technically accurate, and that some people who are new to CNC and looking for an explanation will understand immediately25D (vs 3D) means we will be focusing on pockets (partial depth cuts), profiles (full depth cuts), and inlays (both) With these basic ingredients your creation potential is unlimited!The cnc machines we are using have at least 3 axis, the X, Y and Z axis In the picture X goes from left to right, Y from bottom to top and Z is the depth of the cut Welkom bij RoboCNC Frees en graveerwerk 2D vs 2,5D vs 3D Home

Carveco Maker Powerful Affordable Hobby Cnc Software

3d Stl Models 2 5d 3d Stl Dxf Cnc Model Police Law Etsy

CNC Mill CNC Mill TRex with steel frame – up to 100x4000mm;CNC Machines CNC Router CNC Router HighZ TSeries up to 2100x1050mm;What is the difference between 2D, 25D and 3D contouring?

2d Vs 2 5d Vs 3d Robocnc Frees Graveerwerk

It S Not 3d It S Not 2d It S 2 5d Youtube

If you're just starting out in CNC, it's probably best to start with 25 D instead of 3D for modeling I say this because 3D modeling generally has a longer learning curve For the novice in CNC, there's enough to learn already, so it makes sense to me to start simpler with tools that are easier to learn and to get working An example of the kind of work that you might start with usingFree 3D cnc models for download, files in 3ds, max, c4d, maya, blend, obj, fbx with low poly, animated, rigged, game, and VR options25D vs 3D Working in two and a half dimensions (25D) means you are cutting a part that has multiple flat features at varying depths Most simple CAM programs deal with 25D parts Working in three dimensions (3D) means that you have the ability to control at least three axes simultaneously via

Make Cnc Diy Projects Products Makecnc Com

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

The terms 2D and 3D (as you probably already know) refer to the number of spatial dimensions in a Euclidean worldspace This dimensionality must be an ordinal number;Some History with 2D and 25D All 3 Axis and 4 Axis CNC machines are capable of doing 3D in its fullest 3 Axis interpolation is a term which means that moves made on the machine are smooth in 3D space when using diagonals and curves Some earlier CNC machines were not capable of 3D carving because either their Z axisThe largest CNC machine we make at this time () is the GreenBull 6'x12' model This model has 2 options for Zaxis travel The shortz option has a total Z travel of 575 inches

Live Q A 21 2d Vs 2 5d Vs 3d Carving Youtube

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Most CAM programs support 25D milling Vectric Cut 2D and V Carve do a great job 3D milling refers to the CNC's ability to move X, Y and Z all at the same time in a synchronized fashion to create contoured bottoms, sides and tops of objects Many times this will be called 3D carving of material 2D Versus 3D in CADCAM Software CNC Machine Programming Posted 337 pm Published by Al DePoalo BobCADCAM CADCAM software has everything to do with modern CNC machine programming and plays a critical role in the future success of manufacturing at a global level Manufacturers are continuously looking for solutions to 2D vs 25D vs 3D ICs 101 By Max Maxfield 6 I see a lot of articles bouncing around the Internet these days about 25D and 3D ICs One really good one that came out recently was 25D ICs are more than a stepping stone to 3D ICs by Mike Santarini of Xilinx On the other hand, there are a lot of other articles that have "3D ICs

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Week 2 2 5d Illustrator Desktop Cnc Itp Fabrication

In this presentation we clarify one of the most confusing topics in xray inspection the difference between 2D, 25D, and 3D xray inspection Check the slides toThe code for a 25D machining is significantly less than 3D contour machining, and the software and hardware requirements are (traditionally) less expensive Drilling and tapping centers are inexpensive, limitedduty machining centers that began as a 25axis market category, although many latemodel ones are 3axis because the software and hardware costs have dropped withThe Estlcam 2D, 25D & 3D CAM software is available in English and German Besides, the multilingual CAM user interface offers several other languages (fra, ita, zho, jpn, kor, ndl, pol, por, rou, rus, rus

Solidcam Solidworks

China 2 5d 3d Composite Panel Cnc Engraving Machine For Phone Back Cover China Cnc Machine Cutting Machine

25D vs 3D So far we have only created what are called 25D models, simple extrusions of a crosssection The techniques we learn today will allow us to create "true" 3D models Taper Extrude Simply adding a taper angle to your extrude command can give you interesting volumes Tapered extrusion Tapered extrusion CAD Features and Tips It is just a 25D approach assuming thin metals etc similar to all other 25D engines It is much faster, complements the 3D engine and our designers love to start designs using it But when it comes to sending the wafer layout to the fab we do use the 3D mode and I am happy even if it takes a night before validationYou can best explain this by looking at the cutting result 2D cutting 2D cutting is simply the cutting of contours from a material With 2D cutting, the cutting head from which the water jet comes does not change

Best Free Cam Software In 21 All3dp

2d Vs 2 5d Vs 3d What Do I Need For My Design Formcut

25D is a packaging methodology for including multiple die inside the same package The approach typically has been used for applications where performance and low power are critical Communication between chips is accomplished using either a silicon or organic interposer, typically a chip or layer with throughsilicon vias for communication While communication between chipsWorking in 25D is a very efficient (low machine time) method of creating finishedgoods products and with intuitive software such as Vectric VCarve and Aspire 25D – Simplification of 3D CNC Objects Some routers (usually older models) also lack the ability to simultaneously move the spindle up and down on the z axis while moving on the x or y axes This means that a piece can have different points of different depths, but that the step must be done all at once

Stl 2 5d 3d Vectric Aspire Cut3d Artcam Model Of Clock For Cnc Carving Dragon Clock Es Artcam Artcam Modelsartcam Stl Aliexpress

2 5d Cnc Mill Youtube

Carbide Create can do 25D machining For 3D machining, you can use MeshCAM, which is a paid software but quite powerful 25D machining is when you can move two axes simultaneously ( x and y) and move the third axis (zaxis) while the other two axes are still In 2D machining, you can move the x and yaxis together or independently 25 D is usually a software constraint IE I mainly do 25 work on my router because I only have 25D CAM software The machine itself is capable of In general, 25D refers to multiple silicon dies placed sidebyside on a silicon interposer substrate A "true" 3DIC stack involves two or more dies stacked on top of each other, with interconnect provided by throughsilicon vias (TSVs) Often both 25D silicon interposer and 3D stacking technologies are lumped together under the "3D" label

2d Vs 2 5d Vs 3d What Do I Need For My Design Formcut

3d Vs 2 5d Wood Jigsaw Puzzles And Hobby Cnc Machines Wood Jigsaw Puzzles And Hobby Cnc Machines

CNC 25D AXIS vs VIRTUAL CNC 1 1 10 INTRODUCTION The word "CNC" stands for "Computer Numerical Control" CNC separates between a machine that has a "Controller" on it from one that is manually run CNC software is designed to read CNC programs and initiate a series of machine commands in sequential orderThis cutting head is available for 2D, 25D or 3D cutting What are the differences between these three ways of water jet cutting? 2) 25D edge tempered glass screen protector finishing the edge is deal with CNC polishing, so that the edge has a certain arc, handling feelings is relatively smooth, of course, the process is compared complex, the cost is much higher than the flat edge , is the current mobile phone screen protective film used in the production process

What Is The Difference Between The 2d 2 5d 3d 4d 5d Of The Tempered Glass Screen Protector Product Series Mietubl

Toolpath Planning

Solidcam Cam Software 2 5d Milling

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Shopsabre Operation And Safety Ppt Download

What S The Difference Between 3 Axis 4 Axis 5 Axis Milling Cloudnc

How S That 2 5d Printer Working For You Hackaday

Engraving In Wood 2 5d Youtube

2d Vs 2 5d Vs 3d Robocnc Frees Graveerwerk

2 5d

Shopbot What Is Cnc

2d Vs 2 5d Vs 3d Robocnc Frees Graveerwerk

Help With 3d Carving 43 By Triumfdula Projects Inventables Community Forum

Cnc Machining Vs 3d Printing Make

What Is The Difference Between 2d 2 5d And 3d Contouring Learn Your Cnc

1

China 2 5d 3d Knife Magazine Cnc Carving Machine Manufacturer For Polishing Drilling Milling Chamfering Cutting Carving Engraving China Cnc Engraving Machine Cnc Highlight Machines

Experiments In 2 5d 3d Carving Shopbot Blog

3d Stl Models 2 5d 3d Stl Dxf Cnc Model Police Law Etsy Stl Cnc Things To Sell

Cnc 2 5d Axis Vs Virtual Cnc

How Are Physical Models Created From 3d Designs Shapr3d Help Desk

China 2 5d 3d Knife Magazine Cnc Carving Machine Manufacturer For Polishing Drilling Milling Chamfering Cutting Carving Engraving China Cnc Engraving Machine Cnc Highlight Machines

2 5d Vs 3d 2 5d Vs 3d Cnc Machining 2 5 Axis It Has 3 Axis Control But Only 2 At A Time Are Non Linear While The 3rd Is Only Linear To Understand This Course Hero

Snapmaker 2 0 A Hands On Review Make

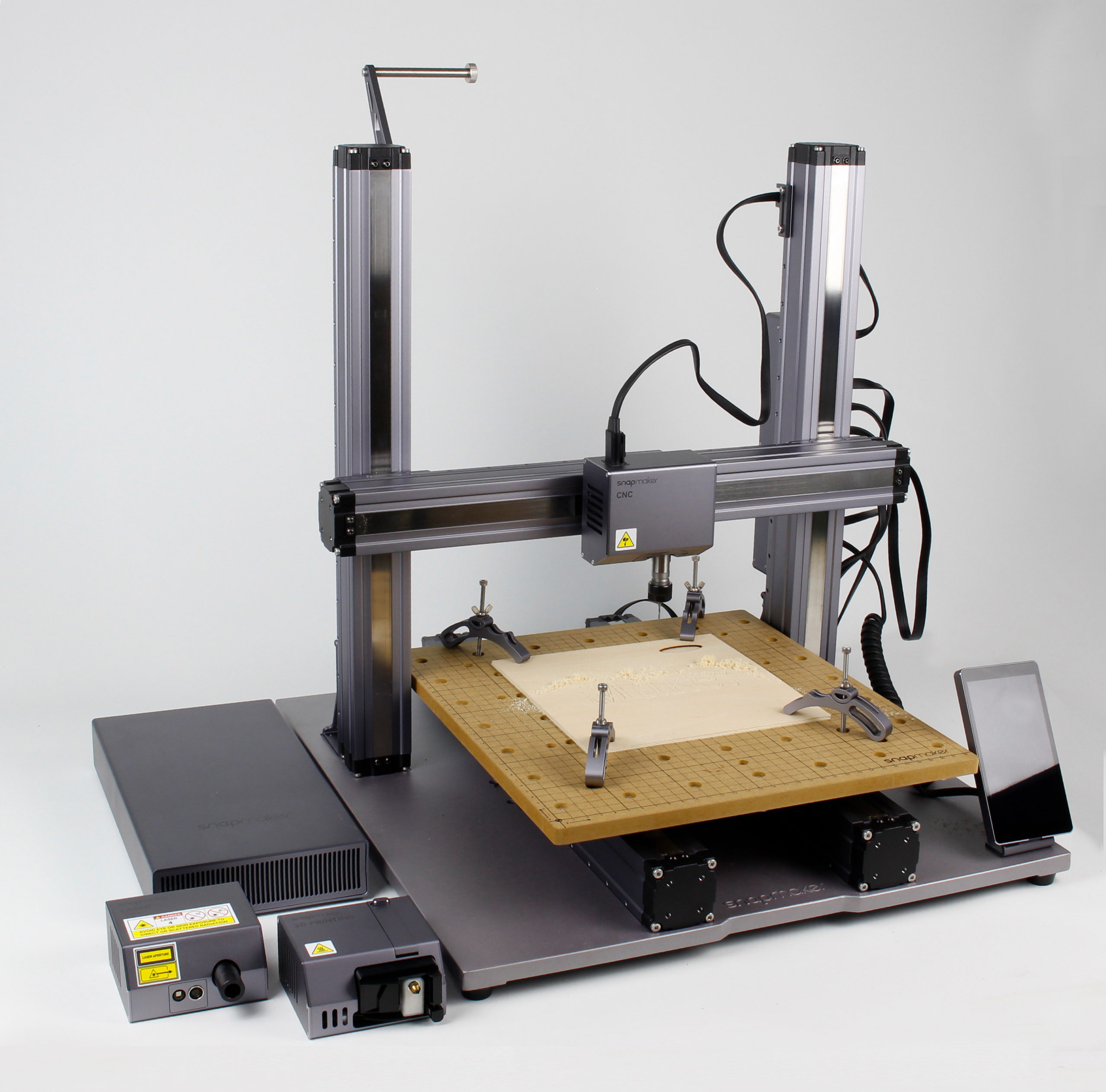

76 New 2 5d Door Design For Cnc Router Cnc Design Hub

3d Vs 2 5d Is It Well Defined The Shapeoko Forum

Experiments In 2 5d 3d Carving Shopbot Blog

Flatcom L Series Cnc Milling Machine Cnc Milling Machine Milling Machine Cnc Mill

Lion 2 5d Router Cnc Tatatronic Youtube

Pin By Elmomen On Projects To Try Cnc Cnc Router World Map

What S The Difference Between 3 Axis 4 Axis 5 Axis Milling Cloudnc

2 5d Animation

3d Vs 2 5d Wood Jigsaw Puzzles And Hobby Cnc Machines Wood Jigsaw Puzzles And Hobby Cnc Machines

How To Do Relief Sculpture Engraving By Omni Cnc Router

Someone Set Me Straight Carbide 3d Community Site

Cnc Plotter 3d Printed Mostly 10 Steps With Pictures Instructables

Flashcut 2 5d 3d Cad Cam Cnc V9 Pro For Mills Routers Flashcut Cnc

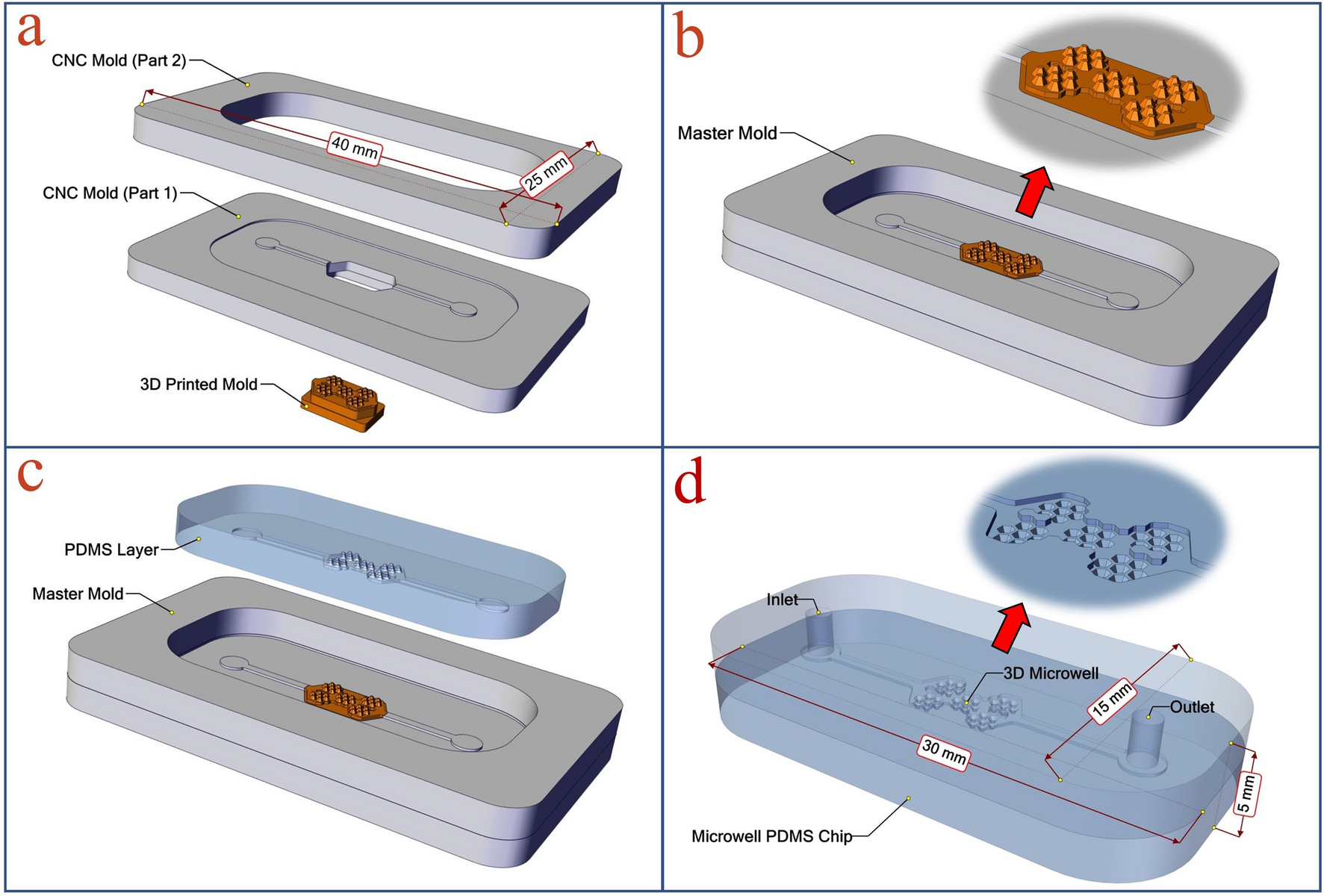

A Combined 3d Printing Cnc Micro Milling Method To Fabricate A Large Scale Microfluidic Device With The Small Size 3d Architectures An Application For Tumor Spheroid Production Scientific Reports

3 Axis 4 Axis 5 Axis Cnc What S The Difference Which Is Best Cncsourced

Cnc Machine Cnc Maintenance Servo Alarm 3 Axis Cnc Machine Vs 2 5 Axis Cnc Machine

8 Computer Controlled Machining Fabrication Embedded Technology Design

Do You Know The Difference Between 2d 2 5d And 3d Cutting Resato

Cnc 2 5d Axis Vs Virtual Cnc

Solidcam Cam Software 2 5d Milling

Estlcam 2d 2 5d 3d Cam Software

4 Axis Cnc Router Machine For 2d 2 5d 3d 4d Router Machine Cnc Router Machine4 Axis Cnc Aliexpress

2d Vs 2 5d Vs 3d Robocnc Frees Graveerwerk

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Stl 2 5d 3d Vectric Aspire Cut3d Artcam Model For Cnc Carving Tree Girl Artcam Artcam Modelsartcam Stl Aliexpress

2d Vs 2 5d Vs 3d What Do I Need For My Design Formcut

First Attempt At 2 5d Routing Cnc

What Is The Difference Between 2d 2 5d And 3d Contouring Learn Your Cnc

What Is The Difference Between 2d 2 5d And 3d Contouring Learn Your Cnc

2d Vs 2 5d Vs 3d Carving Part 36 Vectric For Absolute Beginners Youtube

Make Any Kind Of 2d 3d Carving Models For Cnc Machine By Tanvir Ahmed96 Fiverr

12 Zodiac Signs Stl 2 5d 3d Vectric Aspire Cut3d Artcam Model Of Clock For Cnc Carving 12 Constellations T0017 Woodworking Machinery Parts Aliexpress

Cnc 2 5d Axis Vs Virtual Cnc

China Cnc Router 1530 3d Cnc Wood Carving Machine High Precision Cylinder Cnc Router For Wood Wood Routers Aliexpress

What Is The Difference Between 2d 2 5d And 3d Contouring Learn Your Cnc

Cnc Control Hurco

Cnc Machining The Manufacturing Design Guide Hubs

Cnc Machining Vs 3d Printing Make

1

Carve 2 5d Shapes Out Of Foam With This Arduino Controlled Hot Wire Cutter Arduino Blog

Making A Wavy Look Easel Inventables Community Forum

Cnc Machining The Manufacturing Design Guide Hubs

Cnc Stl 3d 2 5d 2d Models By D J Creations Home Facebook

Make Cnc Diy Projects Products Makecnc Com

2d Vs 2 5d Vs 3d Robocnc Frees Graveerwerk

Cnc Router Clockwork Scenery

It S Not 3d It S Not 2d It S 2 5d Youtube

Sawdust And Noise Cnc Routing Portfolio

3dmodelsart Com Product Creation Of The World 3d Stl Model For Cnc Router 3d Printing Machine Cnc Software Stl

2 5d Hold Down Clamp For Cnc 3d Warehouse

Affordable 3d Cnc Routers 3d Cnc Machines For Sale Stylecnc

China 2 5d 3d Milling Machine Tool Changer Cnc Carving Machine Manufacturer For Polishing Drilling Milling Chamfering Cutting Grinding Carving Engraving China 2 5d 3d Tool Changer Milling Machine Cnc Carving Machine Manufacturer For Polishing

Difference Between 2d 2 5d And 3d 3d Horse

Solidcam Cam Software Hsm 3d High Speed Machining

Carbide 3d

For Milling 2d 2 5d 3d With The Cnc Editor Or Directly Send It To The Machine Other Functions Pdf Document

コメント

コメントを投稿